Took the car to

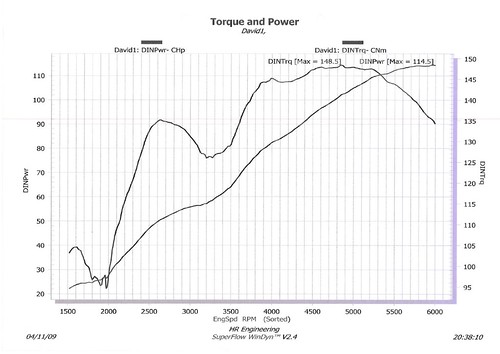

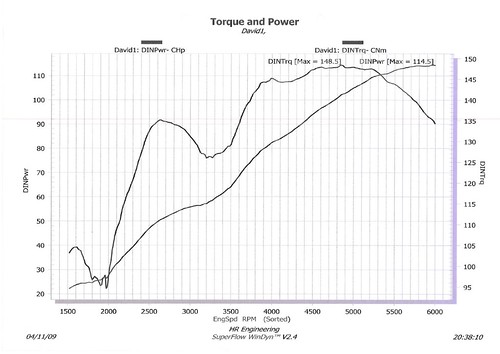

hotrod to get it on the rollers, worked out quite an expensive afternoon but was well worth it, the emulsion jets, main jets, idle jets, and pump jets were all changed, power was up from 114hp to 122hp (And climbing) at 6000rpm which was nice. The midrange has been transformed though, much more torque, and gentle throttle openings are much more responsive now. One carb could do with an overhaul and a new bearing as its sticking, so I'll take that off and replace the bearings soon.

It was over fuelling around 3500rpm causing a big power dip. New emulsion tubes and main jets made a big difference:

Never without a drama, i turned around from the car to go and do something else and was immediately covered in hot coolant, the pipe split between the thermostat housing and the manifold, I guess because its now at a slight angle since i've put the new manifold on, managed not to soak the dyno or computer thankfully. I replaced it with some thicker straight hose and an elbow which Fred had spare. I wonder if that was were my coolant was going.

I've been driving the fury daily this week as the weather has been outstanding, and its doing well, the alternator appears not to be charging properly at the moment although its still starting etc, possibly a loose wire, broken ammeter, or broken alternator so will have a look. The gearbox is also moving on its rear mount so I need to brace it somehow.